Construction of the Tøyenbadet swimming pool complex in Oslo

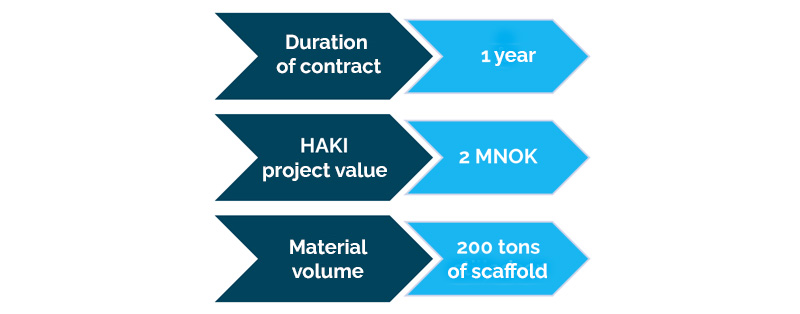

The old Tøyenbadet in Oslo has been demolished and the brand new indoor swimming pool facility is now a work in progress – with HAKI selected as the main shoring and scaffolding supplier together with our customer MB Stillas. Tøyenbadet will be the city's largest swimming facility, and will consist of both an indoor and outdoor area as well as a multifunctional hall. With four indoor pools and a large outdoor swimming facility, this will be a great place for both exercise and play.

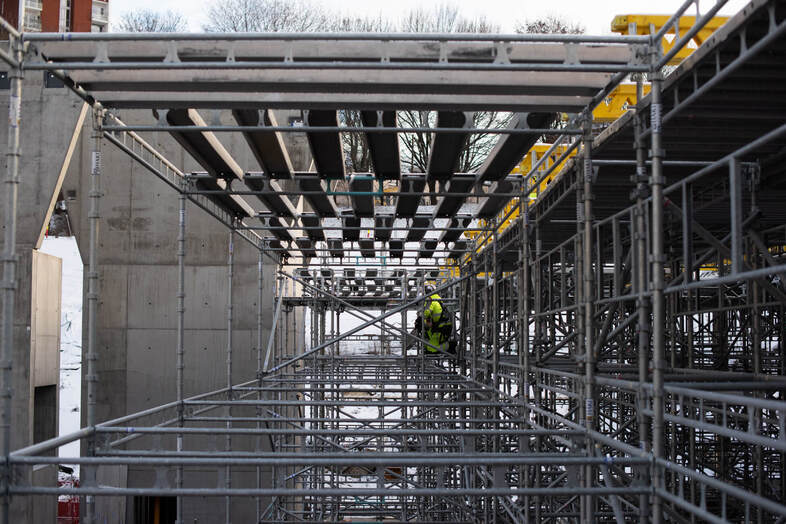

HAKI Universal Shoring supports the unique timber roof

An important piece of this puzzle is building the new architecturally spectacular bathhouse and HAKI are providing a complete shoring solution for the roof. The dramatic roof inside the new Tøyenbadet is going to be made from glued laminated timber (Glulam) which means the roof must be supported with the help of HAKI Universal shoring until it has dried and can support itself. As the roof weighs several hundred tons the planning of the shoring must be precise and it has taken fantastic collaboration to come up with multiple concepts and the best solution.

"We have benefited from being able to deliver digitised concepts with the assistance of HAKI Building Information Modelling (BIM). It helped us to be adaptable and have the ability to come up with different solutions quickly. Typically we build modular scaffolding and tailored access solutions, so erecting shoring to support a roof of this size and weight is an exciting challenge for us” says Dagfinn Mundal, Country Manager at HAKI Norway.

Cooperation, communication and flexibility have been success factors in the sales and planning process.

We have been in close contact with our customer MB Stillas, as there may be changes in the planning and construction process. It is important to keep up to date with changes on the construction site to ensure that the conditions you have for planning and delivery are correct. The cooperation and communication with MB Stillas has been very good, says Patrik Lennartsson, project engineer at HAKI.

Good partnerships produce good results

In addition to our customer MB Stillas, HAKI's team has worked together with several partners on this project, including Woodcon, a leading Norwegian supplier of large wooden constructions. Woodcon have been responsible for the delivery and installation of the glulam.

Being involved from the start has made the planning process easier, which can ultimately save time, materials and money. This also applies to production and deliveries. It is important to have the right prerequisites to make the right calculations and be able to divide the project into logical phases. A project like the Tøyenbadet requires many materials, and the planning of the purchases must be meticulous. When you are at the forefront of production, it is easier to optimize transport, which benefits you both for the environment and costs, says Patrik.

Kristian Borud, CEO of MB Stillas, comments on the collaboration:

"HAKI have been a crucial partner in order to present the best solutions for our customer. Through close tripartite collaboration with HAKI and AF Gruppen, we came up with good and cost-effective solutions. Our BIM technicians have collaborated closely across the companies, which has given us security in terms of HSE (Health, Safety and Environment), quality, solutions and finances".

AF Gruppen, the third largest civil engineering and construction company in Norway, are responsible for all building-related work on this project. As a part of this iconic project they have created a new school visitor centre on site to encourage young people to choose construction and civil engineering careers.

The new Tøyenbadet was completed and opened in January 2025.

Image: Asplan Viak