Universal Scaffold

The modular system HAKI Universal in steel or aluminum is the versatile system for all scaffolding applications, providing maximum productivity across a wide range of structures.

- High strength and safety

- Flexibility in height and width

- Suitable for both light and heavy-duty work

Universal Scaffold

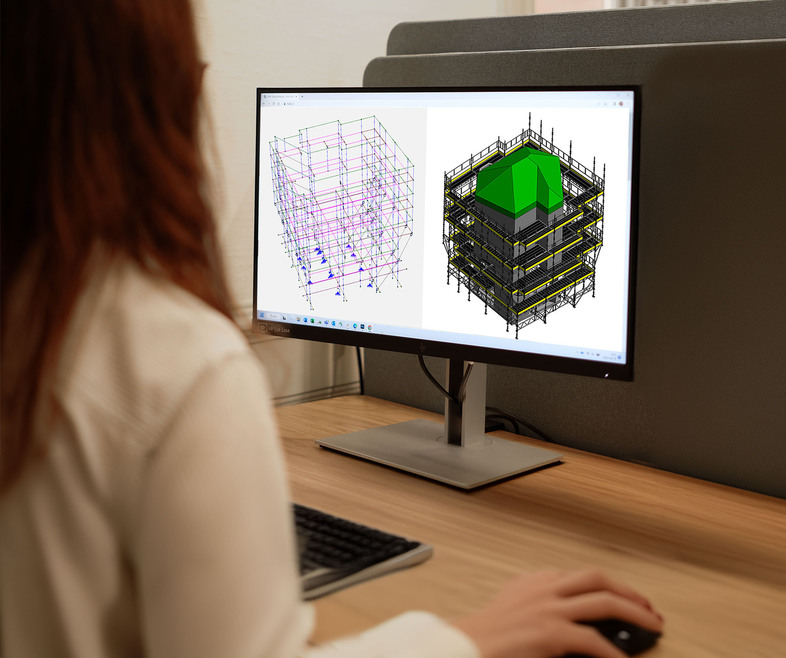

Our Universal scaffolding in steel or aluminium has strong components for high strength and is suitable for those who need a flexible scaffolding solution. HAKI Universal has 7-10 main components with which you can easily and smoothly customise a scaffold and create a variety of designs and solutions, saving working time and increasing productivity.

HAKI Universal is a modular scaffolding system that can be used in simple to highly complex applications in building projects, infrastructure, offshore, shipyards, refineries and industries.

HAKI offers a complete range of Universal products in extremely durable, hot-dip galvanised, high-strength steel and aluminium that comply with global industrial safety standards in a very safe way. Its high adaptability also allows you to safely save labour time and increase productivity in the workplace.

Simply hook on

Our patented simple hook-on method of erection and spring locking catch mechanism of HAKI Universal provides high adaptability with minimal number of components. There are no loose or small fittings, which means minimal moving parts in the design, reducing the risk of component displacement and falling material.

In addition, since you completely avoid the use of tools during assembly and disassembly, you do the job faster and thus more cost-effectively.

HAKI Universal

Our core components

Our Universal scaffolding in steel and aluminium has strong components for high strength and is suitable for those who need a flexible scaffolding solution. HAKI Universal has 7-10 core components with which you can easily customise a scaffold and create a variety of designs and solutions, saving working time and increasing productivity. These components form the basis of the system and can also be used to build other HAKI systems such as stair towers, weather protection and bridge systems.

HAKI Universal enables the construction of a wide range of applications and solution types:

Birdcage

Birdcage scaffolding is a versatile application of HAKI Universal that creates a wide and stable working platform and is optimal for covering hard-to-reach or large areas.

The scaffold can be independent or supported by other structures and requires a stable foundation but does not need to be anchored to a vertical surface.

The design consists of a few basic components but can handle heavy and bulky loads and maximise safety and efficiency in a variety of environments and industries.

Façade

HAKI façade scaffolding is quickly and efficiently installed along the exterior walls of buildings, providing access to the building façade for work such as window replacement, renovation, painting, plastering, repair or installation.

A façade scaffold requires anchoring to the building and a stable foundation on the ground for maximum safety.

Circular

Circular scaffolding is used for cylindrical architecture such as tanks, silos or round towers.

With components from HAKI, rounded solutions are easily created with our core components combined with a few special components. No special solutions with tubes and fittings are required, reducing the volume of equipment from traditional scaffolding.

Thanks to the 7-degree tolerance designed within the pockets, it is possible to turn horizontal components in relation to the standard. The scaffolding can therefore be turned by up to 14 degrees at each standard. When using the three-legged design, the number of buttress bays are reduced by a third around the exterior of the scaffold.

Suspended

A suspended scaffold, also known as a hanging scaffold, is designed to be suspended from any load-bearing overhead structure, allowing work to be carried out at height without the need for ground-based supports.

The multi-functional ledger beam acts as a suspension device while the HAKI Advanced Guard Rail (AGR) can be combined with a double rider to provide leading-edge protection whilst bays are decked out and the second bay is lowered and hooked into place. This way the risk of falls from height is minimised.

HAKI suspension solutions use fewer components compared to other systems available. They can also be up to 30% lower in weight than comparable components, meaning significant reduction of loads into the structure.

Large 3.05m x 3.05m bays can be created using the HAKI Universal System, with fewer contact points and components. Cold formed spigots provide full load-bearing connections between uprights, eliminating the need to use costly tube and fittings.

HAKI components can also carry load as soon as the hook has entered the pocket on a HAKI standard, whereas ring systems require the wedge to be fastened. This means just one person is required to mount a HAKI suspended scaffold, instead of two, which is necessary when using a ring system.

Construction

SHORING

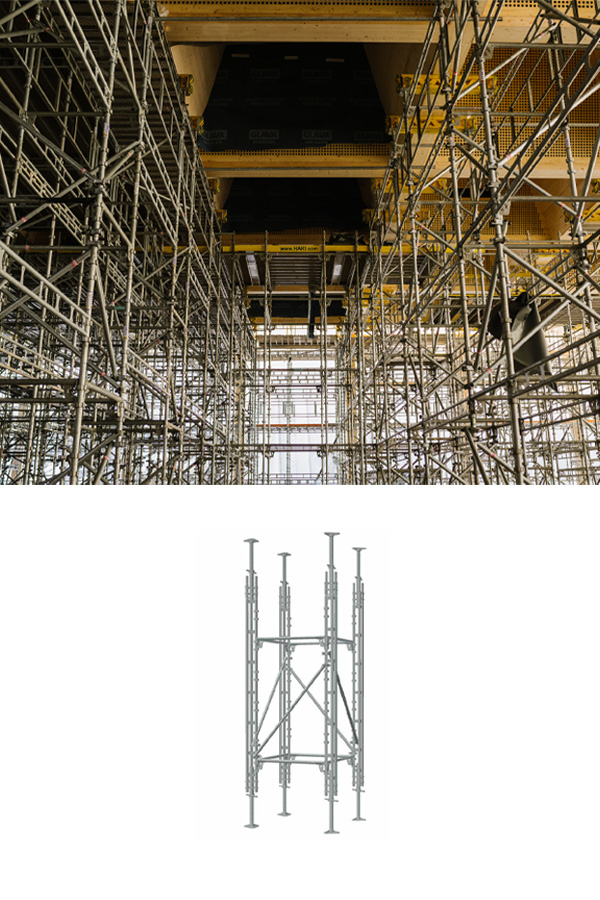

Shoring towers are mainly used to support heavy loads and distribute pressure during construction works that require very strong and stable temporary supports, such as concrete slab pouring, bridge construction and other projects within infrastructure, industry and power plants.

HAKI Shoring consists of HAKI Universal standards, single ledger beams, diagonal braces, horizontal braces, base jacks and fork heads and can be built as independent towers or braced at the top to an adjacent structure, Shoring can be adapted to different heights by adjusting the base jacks at the bottom and at the top.

TRIPOD

HAKI Tripod is often used in combination with HAKI shoring towers and is designed for extremely demanding scaffolding work where the standard load is high, for example in loading towers, bridge supports and tall stair towers. It can also be used for scaffolding bottoming where space is limited and for large anchorage distances with higher standard loads than for normal standards.

HAKI Tripod is fully compatible with HAKI Universal and as horizontals and diagonals HAKI Universal basic components are used.

Intake of materials

Loading and unloading construction materials to workers at different levels of a scaffold is a crucial operation that must be carried out as efficiently as possible without compromising on safety.

LOADING TOWER WITH GUARDRAILS

HAKI loading tower with guardrails is an application of HAKI's modular scaffolding system with HAKI Universal components.

Equipped with guardrail frames on the sides, it ensures safe and efficient intake of materials to and from working platforms or scaffolding, minimises the risk of falls and protects workers at height.

Easy to assemble, dismantle and move, the loading tower can be customised in a variety of different lengths and heights. It can also be placed outside along the scaffolding and can handle heavy and bulky loads.

LOADING TOWER WITH SAFETY GATES

HAKI loading tower with prefabricated, galvanised safety gates is 3050 x 1655 mm and lift heights of 1, 1.5 and 2 m can be achieved.

In addition to the specialised components of safety gates and side panels, the loading tower is built using HAKI's base jacks, standards, beams, steel decks and diagonal braces.

The design of the gates eliminates the need for toe boards and allows for easy and safe transport of materials in and out. The gate can only be opened from the inside, making misuse impossible.

MATERIAL GATE

Ensure unloading of materials on the scaffold or loading tower in a very simple and safe way with a material gate.

The material gate acts as a collective protection and the use of personal fall protection becomes redundant when loading and unloading materials onto the scaffold and does not need to mount and dismount the guardrail.

The material gate is compatible with all HAKI scaffolding systems and works by opening the scaffolding outwards and simultaneously closing it inwards. The lock can then be tilted back so that the scaffolding is closed outwards and it is safe to retrieve the material.

Lighter, stronger, safer

HAKI Universal aluminium

HAKI offers complete modular systems in aluminium. Aluminium components are over 50% lighter than the steel alternative. This not only provides manual handling advantages, but also allows access in harsh environmental conditions where it outperforms its steel counterparts, such as offshore. With its stainless steel qualities, it requires little maintenance, corrodes more slowly than steel and is therefore preferable in humid environments.

Universal scaffolding includes the 100% aluminium HAKI S6 and S4 standards, which are safer and stronger than ever. Our production method of riveted pocket rings maintains the quality of the tubes and pockets of the aluminium standard. Welding can reduce the strength of an aluminium scaffold by up to 40% while riveting does not change the strength. Riveting is a response to HAKI's continuous technical development and quality work for a safer and stronger product.